Manufacturing service for composite industry

Send us your idea

About us

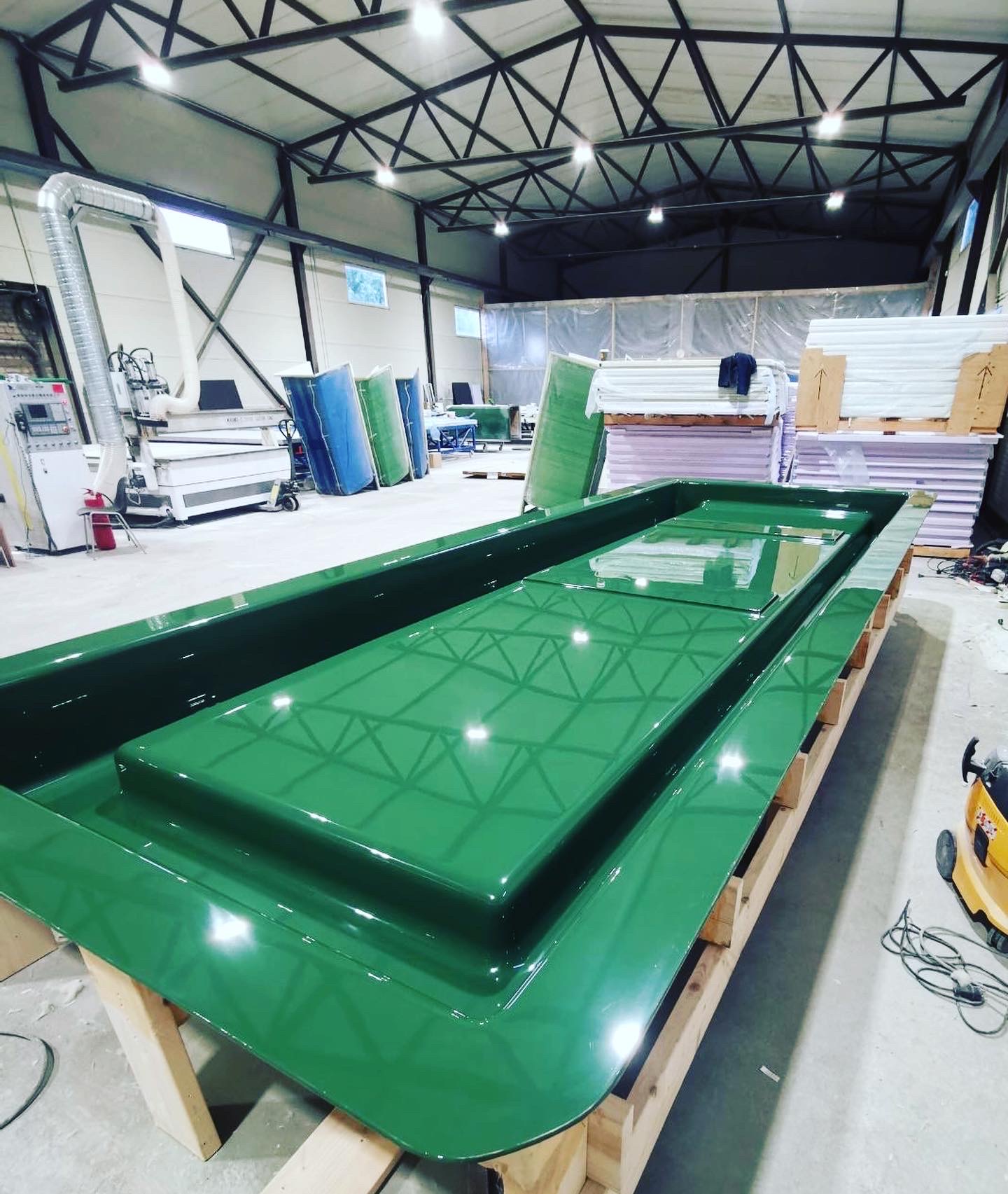

“UAB Stido” is Lithuanian capital company located in the country. Company is expertizing in fiber reinforced plastics and sandwich panel for refrigerators manufacturing. Using glass, carbon, aramid and natural fibers as reinforcement in a combination with polyester, vinylester and epoxy resins. We are experienced and innovative professionals in wet layup, vacuum infusion, light and heavy RTM process. We use hydraulic and vacuum press glue tables. We make our own plugs, moulds and other tools needed for manufacturing process. Production process is precisely planed and controlled according KPI. Company is certified by ISO 9001, 14001 and 45001 standards. Process effectiveness and stability ensured by implemented LEAN management Financial health and future budgets are audited and supported by external company to ensure our customers that we are reliable and stable business partner.

Services

Experienced engineering

2d and 3d

Engineering documentation

Dedicated engineering team is capable to analyze, advice and convert your ideas to drawings, calculations, final tools and products.

Plug and mould

In-house production

Full range of processes till final product

We may design, draw and produce plug, mould, direct mould for your project using foam, wood, composite, steel or aluminium.

Fiber reinforced plastic

(FRP) production

Custom projects, serial production

We may transfer your composite project to reality.

The technologies we use – RTM, Wet layup, Prepregs, Press gluing.

Equipment we have – CNC, Autoclave, Hydraulic and vacuum pressing.

Components

assembly

Fully or semi assembly

We may assemble our produced parts to semi-finished or complete product

We  High tech &

Possibilities

High tech &

Possibilities

From wet layup to autoclave

Trust In Us